| 1.0 Purpose Defining the SENIORLED inspection specifications of LED Panel Lights, and LED Tubes. Making sure they meet the company’s and customers’quality requirements. | |||||

| 1.1 | |||||

| Application The inspection specification is applicable to the LED Panel Light, tubes Semi-finished and finished products inspection. | |||||

| 1.2 Sampling standard | |||||

| 1.2.1 Based on MIL-STD-105E (Ⅱ) single sampling, regular inspection sampling. | |||||

| 1.2.2 Acceptable quality standard(AQL)level: CRI=0 MAJ=0.40 MIN=0.65 | |||||

| 1.2.3 Sampling inspection result classification: Acceptable Reject Waive | |||||

| 1.2.4 Electrical test samples quantity>50PCS inspecting 20%,samples quantity≤50PCS,Inspecting 100%, Accept standard is “0 defect accepted, more than 1 defect rejected” Dimension inspection/Mechanical inspection/Photoelectric inspection each batch sampling 5PCS, accept standard: “0 defect accepted, more than 1 defect rejected” | |||||

| 1.3 Inspection standards, inspection records, reference files | |||||

| 1.3.1 Inspection standards: <> <> <> <> | |||||

| 1.3.2 Inspection records: <> <> | |||||

| 1.3.3 Reference files:<> <> <> | |||||

| 1.4 Defect Definition | |||||

| 1.4.1 Critical Defect (CRI) : Products in the processing, transporting or using processes may have possibility of risking people’s health and/or damaging property. | |||||

| 1.4.2 Major Defect (MAJ) : Defect will cause the loss of the main or most of the product’s functions and/or has bad structure and assembly and therefore will affect the product’s performance. | |||||

| 1.4.3 Minor Defect (MIN) : Defect will cause the product to have some unqualified parts, or nominal appearance damage. Even though it won’t affect the product’s function, it still will reduce the product’s value. | |||||

| 1.5 Inspection Condition | |||||

| 1.5.1 Inspection Method: In distance of 40W fluorescent 1m – 1.2m lighting area, distance between eyes and products is 30cm, visual 3 – 5S. | |||||

| 1.6 Inspection Items and Contents | |||||

| Inspection Objects | Inpection Method and Standard | Inspection tool/Metod | Defect types | ||

| CRI | MAJ | MIN | |||

| 1.6.1 Package Inspection | |||||

| Package Inspection | 1. Make sure the actual quantities are same with the inspection quantity and well organized. | Visual | √ | √ | |

| 2. Boxes (Interior & Exterior) are not damaged. | Visual | √ | √ | ||

| 3. Boxes (Interior & Exterior) Printing, Filling information, Label position, drawing and BOM information are consistent. | Visual | √ | √ | ||

| 4. Label, Material and Content of manual book comply with order and drawing requirements | Visual | √ | |||

| 5. Accessories Specification, Quantity and Order Requirements, Drawing Requirements are consistent | Visual | √ | |||

| 6. No Placement loss (Label loss) Attachment (Specification, Label, Components). | Visual | √ | |||

| 7. Specification and Label are not allowed to be unreadable by pollution or other damage. | Visual | √ | √ | ||

| 8. Ensure products inside package are not loose, package and components are not affected with damp. | Visual | √ | √ | ||

| 1.6.2 Assembling Requirements | |||||

| 1.6.2 Assembling Requirements | 1. No screw mounting loss, peat mounting, using wrong screws, screw Slippage. | Visual | √ | ||

| 2. Metal kits have no rust and/or oxidization. | Visual | √ | |||

| 3. No loose parts (shaken without noise), Deformation, Wrong material usage. | Visual | √ | |||

| 4. Lamp dimension meet requirements,refer to sheet 1(or refer to product specification). | Visual | √ | |||

| 5. Used material has no Chromatic Aberration (If has sample,allowed in the acceptable range) | Visual | √ | √ | ||

| 1.6.3 Lamp Body Label Requirements | |||||

| 1.6.3 Lamp Body Label Requirements | 1. The information on label is clear and correct. 2. Label should be glued flat, tightly. 3. No label missing, repeated label, wrong label or label misaligned. | Visual | √ | √ | |

| 1.6.4 Power Device Inspection Requirements | |||||

| Power Device Inspection | 1. Label is clear with correct information, glue flat and tightly. | Visual | √ | √ | |

| 2. Power device shakes without noise, structure has no loose parts. | Shake | √ | |||

| 3 Input output wire length, Stripping length, Solder length, wire diameter (inner diameter and external diameter) are consistent and same with order (power device approval sheet or samples) requirements. | Visual/Caliper | √ | |||

| 4. If the power device has shaken noise and clatter, Metal is MAJ, Non -metal is MIN | Shake | √ | √ | ||

| 5. Key components on power board (IC, transformer, Electrolytic Capacitor, MOS tube) are consistent with sample or approval sheet. (Inspection based on CDF requirements). | Visual | √ | |||

| 6. Components on power board have no damage, cold solder, moving high, welding spot has non-oxidation. | Visual | √ | |||

| 7. Lamp cover surface has homogeneous color and consistent with the samples, no damage on surface (scratch, needle hole,particle,stain,deformation). | Visual | √ | |||

| 8. Input power, output wire must have prevention measures, and use 35LBS/1min tension at the most difficult direction to pull the wires, the wire movement distance must be no more than 2mm (If it is terminal conductor, the conductor wire movement distance is no more than 1MM) | Trial Assembling | ||||

| Inspection Objects | Inspection Method and Criterion | Inspection Tool/Method | Defect Types | ||

| CRI | MAJ | MIN | |||

| 1.6.5 LED Tube appearance dimension inspection | |||||

| Appearance | 1. Screen print on tube surface, label content clear without any mistake and wrong position. | Visual | √ | ||

| 2. Aluminium surface can not have bigger than diameter 0.4mm Scratch. Embossment, every 0.5m has no more than 3 spots, every 2 spots’ distance is no less than 0.2mm. | Visual Caliper | √ | |||

| 3. No scratch on lamp cover surface, white spot or black spot diameter is no bigger than 0.2mm, every 0.5m has no more than 2 spots, every 2 spots’ distance is no less than 0.2mm. No loose parts inside. | Caliper | √ | |||

| Structure Size | 1. Lamp holder installed in right position with no movement (lamp holder loose movement is no more than 1MM) | Caliper | √ | ||

| 2. Lamp shakes with no noise. (No loose parts inside) | Shake | √ | |||

| 3. PIN needle length between 7.0-7.60MM (use gauge to test),other sizes are in the range of the specification. | Caliper/Gauge | √ | |||

| 4. Tube length meet the requirement. Refer to sheet2(or Product Specification).and tube can not bend to deformation. | Tape/Visual | ||||

| Inspection Objects | Inspection Method and Criterion | Inspection Tool/Method | Defect Types | ||

| CRI | MAJ | MIN | |||

| 1.6.7 Photoelectric Test | |||||

| Finished Product Test | 1. Input product min, max, middle (Market Voltage) light on-off test, products alights normally, no flicker, dark area, strobe, dead lamp, power break, start failure. Product start and delay time is within the qualified requirements. | Variable Frequency Power Intelligent Power Meter | √ | √ | |

| 2. Input the max voltage 1.06 time to has over voltage test, products alights normally, no flicker, dark area, strobe, dead lamp, power break, start failure. Product start and delay time is within the qualified requirements. | Variable Frequency Power Intelligent Power Meter | √ | √ | ||

| 3. The dimming test:using the dimmer match the product brand and type, input nominal voltage, based on min-max-max-min, cycle adjust, dimming smoothly, product alights normally, no flicker, dark area, strobe, dead lamp, power break, start failure. | Variable Frequency Power Intelligent Power Meter | √ | √ | ||

| 4. Lighting process is not allowed to show obvious white spot(s), black spot(s), loose parts, pollutant, light-emitting unevenly, light leak, bright border, yellowing, dark area, chromatic aberration, white spot, black spot in distance 40W fluorescent lamp 1m~1.2m lighting area, distance between eye and products at 30cm, visual 3~5S (as the above photo shows) non-detect is acceptable (quantity is no more than | Variable Frequency Power Intelligent Power Meter | √ | |||

| 5. Test P over P:Nominal Power*±5% (Based on Luminous efficacy standard) Power Factor PF:>0.9 Harmonic:products need to be tested harmonically, need to meet the order requirements. Luminous Flux Lm: meet order requirements Luminous Efficacy LM\W: meet order requirements CRI Ra: meet order requirements SDCM:3000K,4000K,5000K,6500K <6, Beam Angle: Nominal*±25% Uniformity:>80%(select 9 test point) | Integrating Sphere IES Illuminometer | √ | |||

| 6. Aging test time is at least 8 hours, after test, lamp has no dead lamp, flicker, dimmed, dark area, black shadow, obvious chromatic aberration, bad smell and other phenomenons; If the reject ratio is over 3%, need to extend the aging time into 48 hours, products need to proceed 100% short aging test. | Aging Test | √ | √ | ||

| 7. Pressure Test: Connect the product with High Pressure densometers(input wire connect with red,black wire connect with the lamp housing) a. UL test standard: AC test: ClassⅠ 1500V / ClassⅡ 1500V b. CE and TUV test standard: AC test: ClassⅠ 3000V / ClassⅡ 3000V c. Test time: 3S leak current: 5mA d. When LED Panel light proceed pressure test, power and lamp body need to test separately: Lamp body test : AC500V/5mA/1 min Power test : AC3750/5mA/1min Remark: For the above tests, products are qualified without setting off alarm. ClassⅠare first class lamps, has ground earth protection. ClassⅡare second class lamps, without ground earth protection, only have dual electric insulation. | Withstand Voltage Test | √ | |||

| Inspection Objects | Inspection Method and Criterion | Inspection Tool/Method | Defect Types | ||

| CRI | MAJ | MIN | |||

| Finished Products Test | 8, (1) Before vibration test need to confirm if the products’ function and package structure meet requirements,test time is 1 hour (2) After test proceed half an hour, need to adjust (First vibrate the position at products original place, then rotate 90°to proceed the test) (3) In this process, must consider that product can not be blocked. After tests the product must meet the following requirements: 1. No components broken, scratched, loose or stripped; 2. LED Panel Light can operate normally, no functions damaged; 3. LED Panel Light Input Power, Power Factor and Electric Strength test is normal; 4. Package has no damage, seal point tampered and other damages. | Vibration Tester | √ | ||

| 9, Drop Test: Products need to have drop test, refer(sheet 3) operation, products are without damage after test. | Operate | √ | |||

| others | 1. Make sure the qualified products meet standard requirements and put them back to the original position. | ||||

| 2. Recording the results in the report. | |||||

| LED Tube Dimension | |||||

| Type | Real size:L*D (without PIN) | Real size tolerance (without PIN) | PIN size | ||

| T8-6W-60-HC | 588*26 | 588+1mm/-0.5mm | 7.0-7.60MM | ||

| T8-12W-120-HC | 1198*26 | 1198+1mm/-0.5mm | 7.0-7.60MM | ||

| T8-16W-150-HC | 1498*26 | 1498+1mm/-0.5mm | 7.0-7.60MM | ||

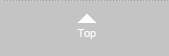

| Drop Test(Sheet 3): According to GB4857.5 package test method, follow 1 angle 3 border and 6 sides drop sequence to test. According to the actual package method, choose the drop angle which near from the package center of gravity, treat the 3 border connect with the same drop angle as the dropped border. Carton Package Drop Test standard: | |||||

| Carton Package’s standard are based on the following factors: A type: Products do not meet B type standard B type: Total weight>100kg (220.5lb) or Total weight<=100 kg (220.5lb) and with pallet. Sheet 4-7 A type Carton Package Impact Standard | |||||

| Weight(kg) | Drop Height(mm) | Lift Method | |||

| 0 to 10(0~22lb) | 750(29.5in) | Single person throw | |||

| 10 to 25(22~55.1lb) | 600(23.6in) | Single person lift | |||

| 25 to 50(55.1~110.2lb) | 525(20.7in) | Two People lift | |||

| 50 to 100(110.2~220.5lb) | 450(18.5in) | Two People lift | |||

| Sheet 4-8 A type Carton Package Impact Standard | |||||

| Weight(kg) | Drop Height(mm) | ||||

| 0<450(992lb) | 300(11.8in) | ||||

| 450 or big than 450 lb) | 150(2.9in) | ||||

| Diagram Drawing,Surface S1, S2, S3 Side E1, E2, E3 Angle C1, C2, C3, C4 | |||||

|

|||||

Jackson

Jackson

sales01@newlamp-lighting.com

sales01@newlamp-lighting.com