High-power LED lamp beads characteristics and technical parameters

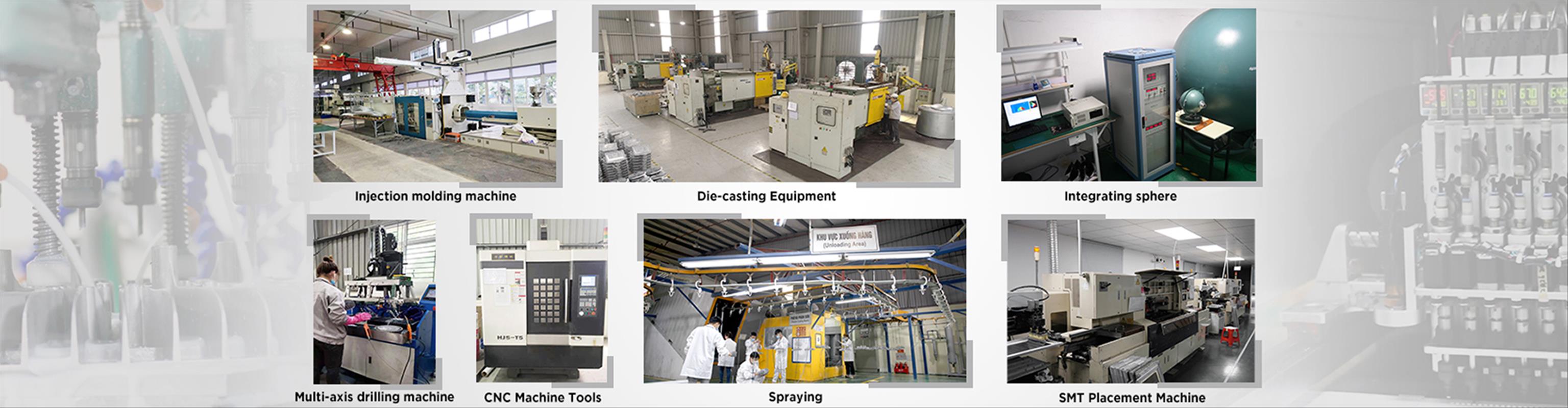

The company is located in:

High-power LED lamp beads are a kind of LED lamp beads. Compared with low-power LED lamp beads, the power of high-power LED lamp beads is higher, the brightness is brighter and the price is higher. Low-power LED lamp beads are 20mA rated current, rated current higher than 20mA can basically be considered as high-power. The number of general power: 0.25w, 0.5w, 1w, 3w, 5w, 8w, 10w and so on. The main unit of brightness lm (lumens), low-power brightness unit is generally mcd (millicandela, 1cd = 1000mcd), which is the luminous intensity I.

1cd = 1lm / sr (lumens / stereo) = 1 candlelight. The explanation is as follows: the luminous flux emitted by the light source within the solid angle dΩ in the specified direction or the luminous flux dΦ transmitted by the light source, and the quotient of the two is the luminous intensity I (in candela, cd). Housing available PC pipe production, high temperature of 135 degrees.

High Power LED Product Category:

Currently as a new green, environmentally friendly, energy-saving light source is widely used in car lights, flashlights, lamps and other places. The reason why LED power is so called, mainly for low power LED, the current classification of the standard summed up in three ways:

The first is based on the size of the power can be divided into 0.5W, 1W, 3W, 5W, 10W .... 100W ranging, depending on the total power of the molded package after the product is different and different.

The second can be divided according to their packaging process is divided into: large-size epoxy package, imitation piranha epoxy package, aluminum plate (MCPCB) package, TO package, power SMD package, MCPCB integrated package and so on

The third can be based on the degree of light failure can be divided into low-light high-power products and non-low-light high-power products.

Of course, due to the high-power LED itself more parameters, according to different parameters will have different classification criteria, no longer described here. LED high-power LED package is still one of the products in the field, is to make the semiconductor lighting to the field of general lighting the most important part.

High-power LED product application considerations

High-power LED products and devices in the application process, cooling, electrostatic protection, welding has a great influence on its characteristics, the need to cause the application end customers attach great importance.

First, high-power LED product cooling:

Due to the current semiconductor light-emitting diode chip technology limitations, LED photoelectric conversion efficiency still needs to be improved, especially high-power LED, because of its high power, about 60% of the electricity will become heat release (with the development of semiconductor technology , The photoelectric conversion efficiency will gradually increase), which requires end customers in the application of high-power LED products, to do a good job of cooling to ensure the normal operation of high-power LED products.

1. Heat sink requirements

Appearance and Material: If the finished product is not required to be sealed, convection can occur directly with the outside air environment. It is recommended to use finned aluminum or copper heat sink.

2. Effective cooling surface area:

For 1W high-power white LED (other colors are basically the same) our company recommended heat sink effective cooling surface area of ≥ 50-60 square centimeters. For 3W products, it is recommended that the effective radiating surface area of the radiating fin be ≥ 150cm2, and the higher power should be increased as the case may be and the test result should be increased to ensure that the temperature of the radiating fin does not exceed 60 ℃.

3. connection method:

When connecting the high-power LED substrate with the heat sink, ensure that the two contact surfaces are flat and in good contact. To enhance the combination of the two contact surfaces, it is recommended to apply a layer of thermal grease on the bottom of the LED substrate or the surface of the heat sink (the thermal conductivity ≥ 3.0W / mk), thermal grease requirements uniform coating, the right amount, and then screw-pressed fixed.

Second, high-power LED products electrostatic protection

LED is a semiconductor device, is more sensitive to static electricity, especially for white, green, blue, purple LED to do to prevent static electricity and eliminate static electricity work.

1. Electrostatic generation:

① friction: In everyday life, any two objects of different materials contact and then separated, you can generate static electricity, and the most common method of generating static electricity is triboelectric generation. The better the insulation of the material, the easier it is for triboelectric generation. In addition, any two objects of different substances contact and then separated, can also generate static electricity.

② Induction: For conductive materials, due to the free flow of electrons on its surface, such as placing it in an electric field, due to same-sex repulsion, opposite sex attraction, positive and negative ions will be transferred in its surface will have a charge .

③ conduction: For conductive materials, due to the free movement of electrons in its surface, such as contact with charged objects, charge transfer occurs.

2. Electrostatic damage to the LED:

① due to the transient electric field or current generated heat, LED local injury, the performance of the rapid increase of leakage current, still work, but the brightness is reduced, life expectancy is impaired.

② electric field or current damage LED insulation, the device does not work (completely destroyed), the performance of dead lights.

3. Electrostatic protection and elimination measures:

For the entire process (production, testing, packaging, etc.) all direct contact with the LED staff should do to prevent and eliminate static electricity measures, there are

1, anti-static floor laying shop and well grounded.

2, the workbench is anti-static workbench, the production machine is well grounded.

3, the operator wear anti-static clothing, with anti-static bracelet, gloves or foot ring.

4, the application of ion fan.

5, soldering iron to do the grounding measures.

6, anti-static packaging materials.

Third, high-power LED product welding

1, please pay attention to the best selection of soldering temperature soldering iron, soldering temperature is below 260 ℃, soldering iron and LED pad contact time does not exceed 3S;

2, such as silicone encapsulated high-power LED, the maximum heat-resistant temperature of silicone is 180 ℃, so the LED's welding temperature shall not exceed 170 ℃, the use of low-temperature soldering iron and low temperature solder paste (wire) welding, The time does not exceed 3S.

Related News

- LED High Bay Light Brief Introduction

- Vietnam LED lighting market has become the emerging focus?

- LED Outdoor Lighting

- Hong Kong-Zhuhai-Macao Bridge

- LED lamp bead welding process dead lamp reason

- Why there is no street light on the highway? - Dec 29, 2017 -

- LED packaging process, how to do a good job of anti-sulfur measures

- RGB LED three white LED forming principle

- Improve the light extraction efficiency of thermal resistance power LED pack

- LED packaging Collection: I do not know the LED packaging process knowledge

- LED driver power potting use

- LED flip chip technology and process analysis

- Experimental Study on Improving the Temperature Resistance of LED Light Source

- LED Floodlight structure

- Advantages of Driverless Floodlights

- LED flood light installation instructions

- Advantages Of LED Floodlight

- LED flood light applications

- LED six technology to lead the future

- Small out of the high light flux density under the trend of LED package substrate

Jackson

Jackson

sales01@newlamp-lighting.com

sales01@newlamp-lighting.com