Experimental Study on Improving the Temperature Resistance of LED Light Source

Introducing a WFCOB light source

A WFCOB light source

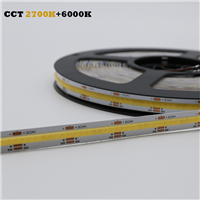

The COB light source manufactured by the groove (W) and fluorine (F) hose frame, referred to as WFC0B light source

First, the technical background

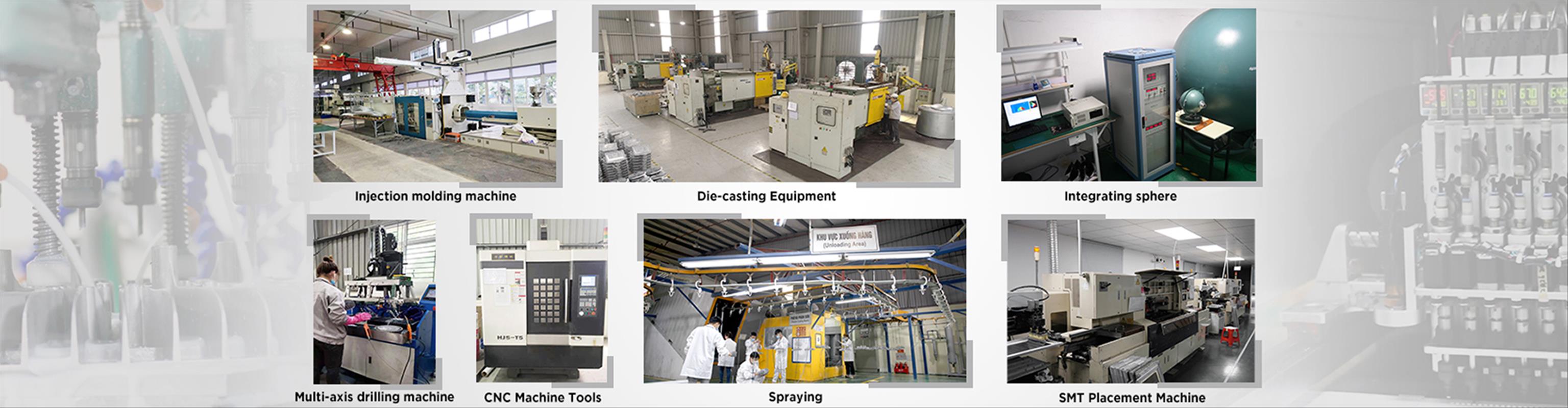

Compared with the single-chip package, the COB package has many advantages in light intensity, heat dissipation, light distribution and cost. Compared with multiple low-power arrays, the light intensity and the heat dissipation in parallel can effectively increase the light intensity / heat resistance ratio, Resistance is low, currently occupy the market There are three main COB light source system, but they all have the following disadvantages:

1, COB light source with PCB board and aluminum substrate lamination process Disadvantages: At present, the best thermal conductivity of pressed aluminum substrate is only about 2.0 / mK, while the thermal conductivity of pure aluminum is 237 / mK, a difference of more than one hundred times , Such a large package thermal resistance, heat consumption will inevitably increase, resulting in serious light failure. Due to the use of adhesives at high temperature work easy to crack off, combined with a large insulation resistance between layers, use it to do high-power package (20W above) damage failure rate is high.

2, the COB light source composed of multiple SMD low-power arrays Disadvantages: It relies on aluminum substrate and reflow, multi-layer thermal resistance more intolerant of high temperature.

3, to the integrated light source of injection molding process Disadvantages: The use of plastic injection molding process will be embedded in the PPA plastic plate, PPA under high temperature and ultraviolet light will turn yellow and even chalking, easy to harden, crack, off the gold line, resulting Breathable water, the failure rate is high. As the copper substrate requires silver plating process, will pollute the environment, high cost, easy oxidation. This bracket structure due to electrode lead plate higher than the chip 1.5mm, the phosphor and gel a large amount of colloidal too thick not only affect the light transmission, but also increase the packaging costs.

Second, break through the traditional, new standard innovation; different, self-contained system

1. Innovative ideas:

Improve the temperature resistance of light source, completely solve the shortcomings of traditional light sources, improve its function and performance, low thermal resistance, high light efficiency, simple structure to the extreme, the system cost is greatly reduced, so that the packaging plant and lighting plant have benefits.

2. Technical measures:

*, LED chips and direct thermal substrate solid crystal, completely eliminating the aluminum substrate thermal insulation barrier.

*, The use of trench technology, completely eliminating the need for another dam technology,

*, Using bright aluminum mirror, completely eliminating the silver plating process.

*, The use of high temperature insulation materials, completely eliminating the need for integrated stent injection molding process.

*, Trench dam technology completely eliminates the aluminum substrate lamination process.

Compared with the existing three traditional system light sources, the WFC0B light source of the invention has the obvious advantages that: 1. The integrated structure of the metal is used to eliminate the integrated light source injection molding process, thereby not only improving the temperature resistant property of the light source but also completely solving the problem that the PPA High temperature and ultraviolet light will turn yellow, powder, breathable and cause product failure.

2. The use of high temperature insulation tight electrode plate technology, and get rid of the COB light source on the aluminum (copper) substrate bonding process relies on not only improve the light source temperature characteristics also completely solve the aluminum (copper) substrate high thermal resistance, not easy Wiring and welding, high temperature operation and many other drawbacks off.

High light efficiency: The general common chip, light efficiency can reach 130-160 / LW

Temperature test: small 3 my radiator, 20 light source radiator temperature of 148 degrees, continuous 24 hours of continuous work is not bad, more than 200 degrees colloid temperature can light cigarettes.

3. The use of high-reflective mirror aluminum, leather substrate in addition to silver plating process, completely overcome the silver plating process brings the high cost, easy to vulcanization and other drawbacks.

4. The use of trench technology, not only reduces the amount of fluorescent glue, but also to overcome the COB light source plastic dam due to absorption of light caused by the drawbacks of low luminous efficiency.

5 due to improved light source temperature characteristics, reducing the package thermal resistance, not only can reduce the amount of heatsink, but also increase the chip operating current, increase light intensity, saving lamp manufacturing costs.

6. As the light source to improve the temperature characteristics, low light failure, effectively reduce the reliability of the light source and prolong the service life.

7. Because of the exclusion of the integrated light source of PPA and COB light aluminum substrate insulation resistant materials and inks, can facilitate the adoption of the relevant certification.

8. Whether it is made from the stent, light source packaging and lamp making and other aspects can significantly reduce costs, a multi-technology benefit.

Conclusion

A breakthrough WFCOB light of the original, the world a new unique, unique, self-contained system, the obvious technical advantages of the packaging plant and lamp factory benefit from many, technological innovation will break the industrial pattern, and ultimately promote the rapid development of LED industry!

Related News

- LED High Bay Light Brief Introduction

- Vietnam LED lighting market has become the emerging focus?

- LED Outdoor Lighting

- Hong Kong-Zhuhai-Macao Bridge

- LED lamp bead welding process dead lamp reason

- Why there is no street light on the highway? - Dec 29, 2017 -

- LED packaging process, how to do a good job of anti-sulfur measures

- High-power LED lamp beads characteristics and technical parameters

- RGB LED three white LED forming principle

- Improve the light extraction efficiency of thermal resistance power LED pack

- LED packaging Collection: I do not know the LED packaging process knowledge

- LED driver power potting use

- LED flip chip technology and process analysis

- LED Floodlight structure

- Advantages of Driverless Floodlights

- LED flood light installation instructions

- Advantages Of LED Floodlight

- LED flood light applications

- LED six technology to lead the future

- Small out of the high light flux density under the trend of LED package substrate

Jackson

Jackson

sales01@newlamp-lighting.com

sales01@newlamp-lighting.com